Direct to garment (DTF) printing revolutionizes apparel production by directly applying ink to fabric, resulting in vibrant, durable designs with superior color accuracy. Using high-quality cotton or blends and optimized artwork transfers ensures excellent print quality on DTF Printed Shirts. Calibrating equipment and pre-treating fabrics enhance precision and color matching, while fast delivery services streamline the process for businesses and designers seeking affordable, custom apparel solutions.

“Unleash your creativity with the art of printing high-quality graphics on DTF (Direct to Fabric) printed shirts. This cutting-edge technique revolutionizes custom apparel, offering vibrant and durable designs. In this guide, we’ll explore the benefits of DTF printing for shirt graphics, from its precise color reproduction to fast turnaround times. We’ll also uncover essential tips for selecting top-tier materials and master techniques to ensure your prints stand the test of time. Elevate your garment game with these insights and bring your design visions to life.”

- Understanding DTF Printing and its Benefits for Shirt Graphics

- Choosing the Right Materials for Optimal Print Quality

- Techniques to Ensure Vibrant and Long-Lasting Designs on DTF Printed Shirts

Understanding DTF Printing and its Benefits for Shirt Graphics

Direct to garment (DTF) printing is a cutting-edge technique revolutionizing the way we produce high-quality graphics on shirts and other textiles. Unlike traditional printing methods, DTF allows for direct application of ink onto the fabric’s surface, resulting in vibrant, durable, and precise designs. This process ensures that every detail of the graphic is reproduced accurately, making it an ideal choice for custom apparel creation.

One of the key benefits of DTF printing is its versatility. It accommodates a wide range of design complexities, from simple text to intricate illustrations. Moreover, DTF Printed Shirts offer superior color accuracy and a soft, comfortable feel. The technique also eliminates the need for costly set-up costs typically associated with traditional printing, making it an efficient and cost-effective solution for small runs or custom orders. Understanding these advantages positions creators and businesses to harness the potential of DTF application instructions and design requirements to craft outstanding, unique garments.

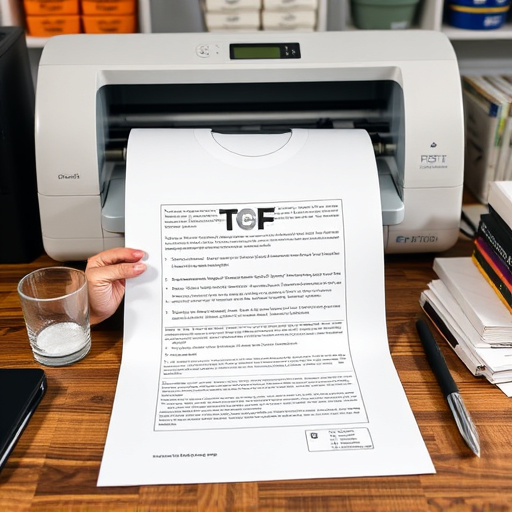

Choosing the Right Materials for Optimal Print Quality

When creating DTF Printed Shirts, selecting the appropriate materials is paramount for achieving exceptional print quality. The fabric’s composition and weight significantly impact the final outcome. Opting for high-quality, breathable cotton or blends ensures a smooth surface for printing, enabling intricate details and vibrant colors to be reproduced accurately. This is particularly important for detailed designs where precision matters.

Moreover, considering the dtf cost-effective nature of this printing method, choosing the right materials also influences overall production costs. Custom DTF gang sheets, which allow for efficient printing on multiple shirts simultaneously, can significantly reduce per-unit pricing while maintaining fast dtf delivery. This makes it an attractive option for businesses and designers looking to offer high-quality custom apparel without breaking the bank.

Techniques to Ensure Vibrant and Long-Lasting Designs on DTF Printed Shirts

To ensure vibrant and long-lasting designs on DTF Printed Shirts, several techniques can be employed. First, use high-quality DTF artwork transfers that are optimized for ink adhesion and color accuracy. These transfers should be created with meticulous attention to detail, ensuring precise lines and rich color palettes. Additionally, proper preparation of the shirt surface is crucial; pre-treating the fabric to increase absorbency enhances ink retention.

For exceptional results, achieve accurate dtf color matching by calibrating your printing equipment regularly. Use industry-standard profiles and software to match colors precisely from design creation to printing. Moreover, consider fast delivery options when ordering DTF printed shirts to minimize the time between design approval and receipt of the final products, ensuring timely feedback loops for any adjustments needed.

DTF (Direct to Fabric) printing offers a cutting-edge solution for creating high-quality graphics on shirts, allowing for vibrant designs that endure. By selecting the appropriate materials and mastering print techniques, you can produce exceptional, long-lasting garments. This method revolutionizes the way we approach custom shirt design, ensuring your creative vision is accurately represented on each fabric canvas.